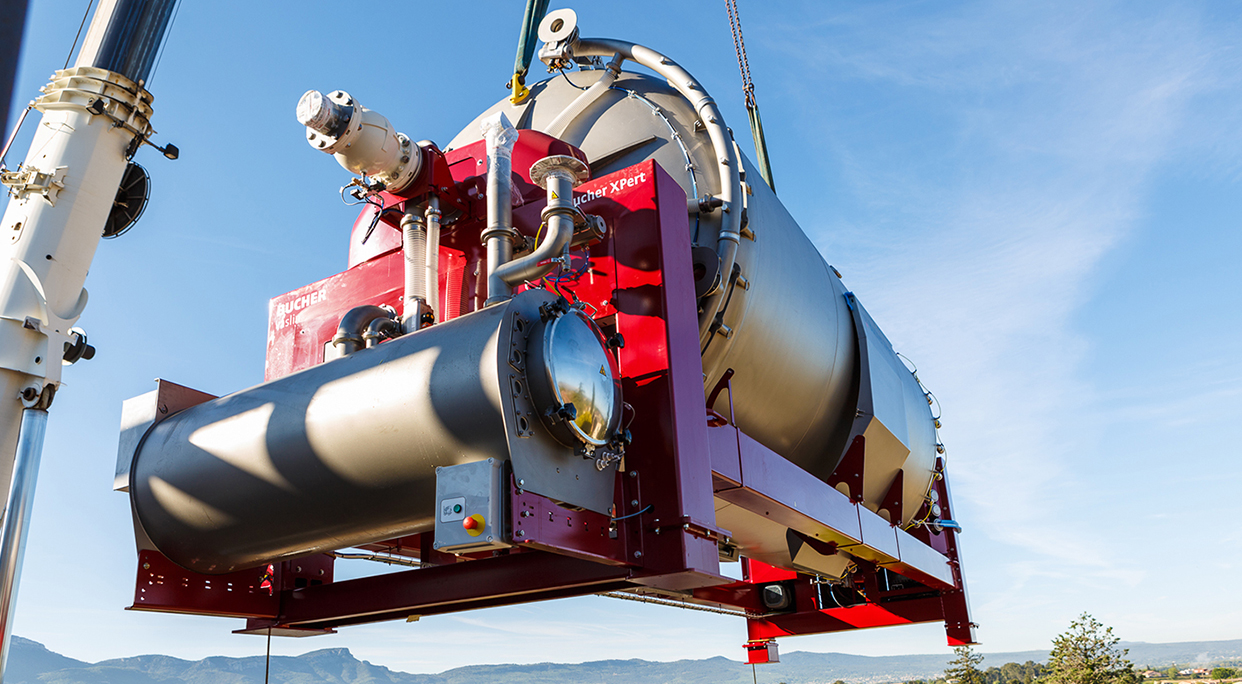

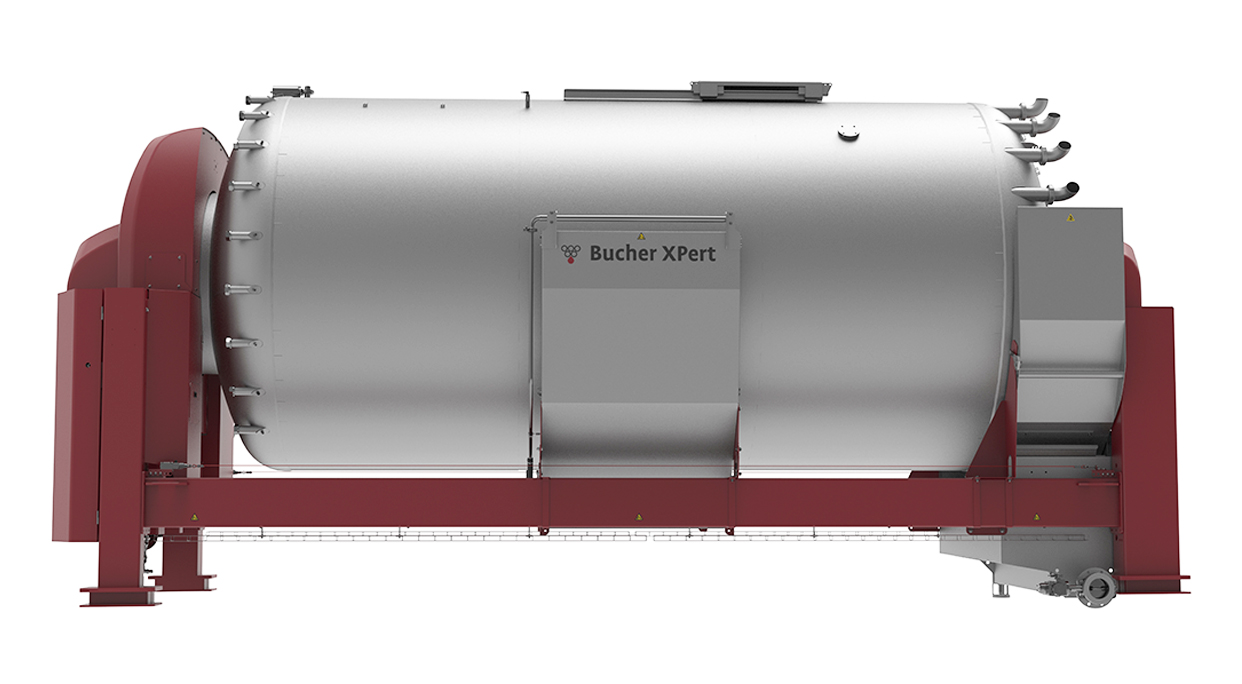

Closed cages

Closed-cage presses are the ideal solution for maceration, inerting, and completely controlled pressing.

More information

Open cages

Our presses are equipped with open cages for rapid draining without self-filtration of juice, and easy tank cleaning. Discover the…

More information

Vertical presses

Bucher JLB vertical presses are the fruit of a synergy between modernity and local tradition, the vertical press fits perfectly…

More information

Engineering

Do you have a specific need? Cave’s engineering department is here to help. Our key words? Implementation, feasibility, specific or…

More information