News

Press releases

Lyna Pervélys, automatic management of dissolved gases

Press releases

Flavy FGC 1-2-3-4

The latest innovations

The world of wine is in full swing and Bucher Vaslin is constantly looking for innovations to meet new challenges. This is reflected in the technological patents registered each year and in the product tests carried out with you during the harvest in all hemispheres.

Bucher Origin CO

Bucher Vaslin offers you a return to our roots, the Bucher Origin open-cage pneumatic press, as close to our origins ...

More information

Bucher Origin CF

Bucher Vaslin offers you a return to our roots, the Bucher Origin closed-cage pneumatic press, as close to our origins ...

More information

Delta Oscillys XM/XL

Delta Oscillys XM / XL relies on the high amplitude oscillation of a cage to detach the grapes from the ...

More information

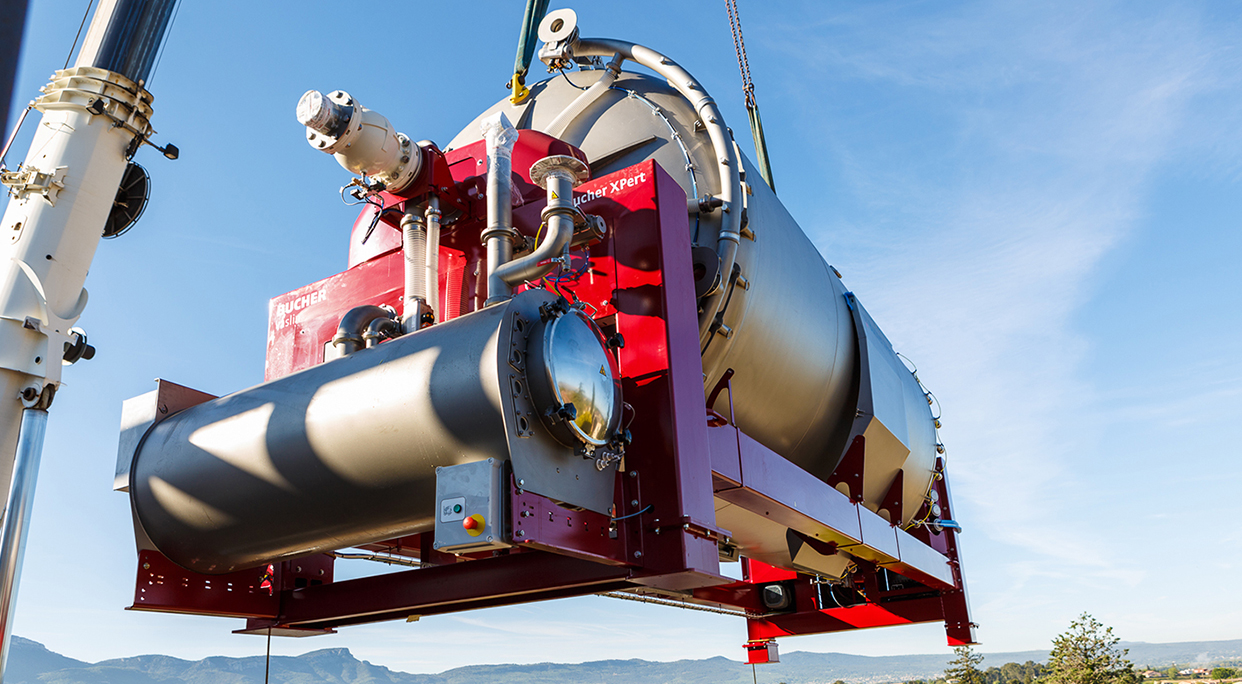

Flavy FGC

The High Capacity Filter, Flavy FGC, is an amalgam of technologies meeting the challenges of industrial structures.

More information

Retrofit

Our Retrofits help you to make an ecological transition by preventing machines from becoming obsolescent while preserving their original structure.

More information

Our experience

Bucher Vaslin offers the winery all the answers to the winegrower’s needs, from grape harvest treatment to wine filtration.

Our catalogues

Find a dealer

Selected for their professionalism, Bucher Vaslin dealers advise you and guarantee quality local service.

Join us

Interested in a career with Bucher Vaslin? Take a look at our job offers or apply directly on our website.

Contact us

For further information, please contact Bucher Vaslin.