Reduce your electricity consumption

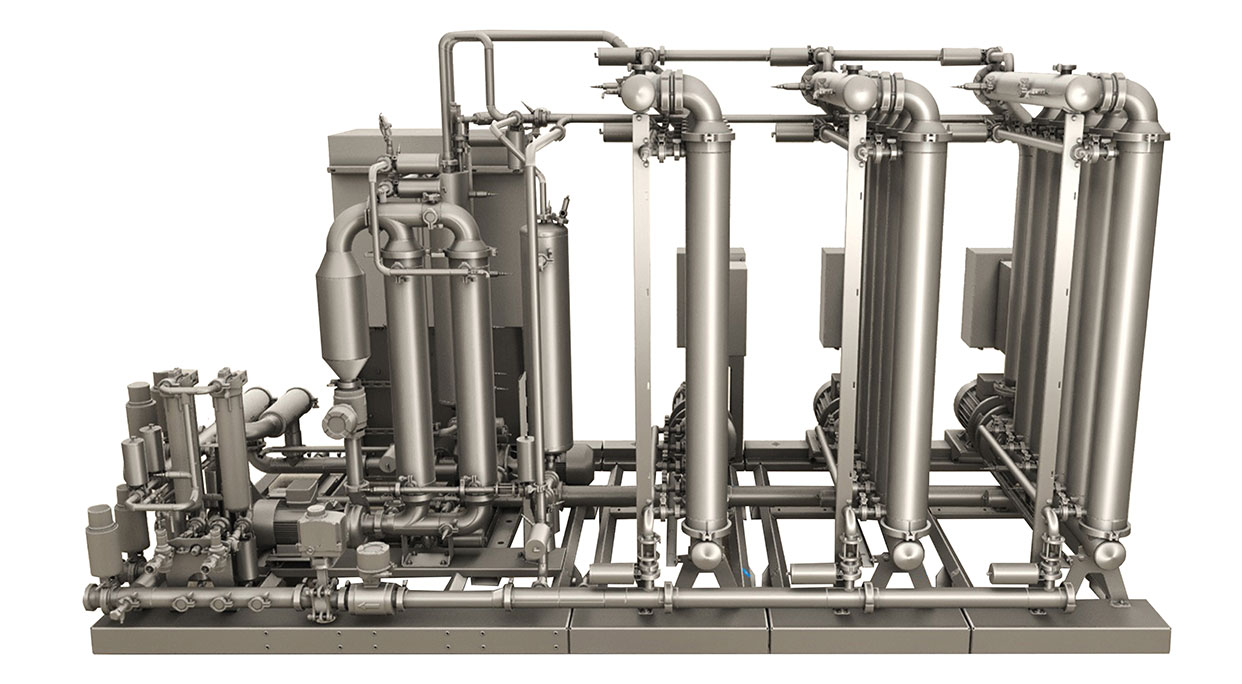

The major innovation of the Flavy FGC filter is the automatic adaptation of its operating parameters according to the profile of the wine to be treated. As a result, the filter has a very low carbon footprint, thanks to its greatly reduced electricity consumption (divided by 2 on average and by 30 for white wines compared with tangential filters on the market).

Increase your productivity

All the technological advances and innovations in the Flavy FGC range have resulted in high productivity, with volumes of rejects reduced to unprecedented levels and consumption of electricity, water and cleaning products at record lows.

Improve your working conditions

The Flavy FGC filter provides real comfort and increased peace of mind for cellar operators thanks to its simple and easy operation, its maximum safety (e.g. safety against a connection error on a tank bottom), and its very low noise level during operation.

Finally, the Flavy FGC filter follows in the footsteps of the Flavy X-Wine filters, which are renowned for their quality preservation of filtered wines and their rock-solid reliability.

| Technical data | FGC 1 | FGC 2 | FGC 3 | FGC 4 |

|---|---|---|---|---|

| Length (mm) | 2800 | 3600 | 4400 | 5200 |

| Width (mm) | 2440 | 2440 | 2440 | 2440 |

| Floor area (m2) | 6.5 | 8.2 | 10.7 | 12.6 |

| Height (mm) | 2510 | 2510 | 2510 | 2510 |

| Unladen weight (kg) | 1600 | 2100 | 2700 | 3300 |

| Water weight (kg) | 1900 | 2700 | 3,500 | 4300 |

| Supply voltage (V/Hz) | 400 Volts three-phase + Earth (50 Hz) | 400 Volts three-phase + Earth (50 Hz) | 400 Volts three-phase + Earth (50 Hz) | 400 Volts three-phase + Earth (50 Hz) |

| Total power (kW) | 30 | 40 | 50 | 60 |

– Makes it possible to separate washing water from the last filter rinsing water

– Recover this clear water for other uses

– Helps reduce water consumption in the cellar

– In the case of water with a fouling index > 3, we recommend installing 3 stages of water filtration (5 µ – 1µ – 0.5 µ) for maximum efficiency of rinsing and washing operations.

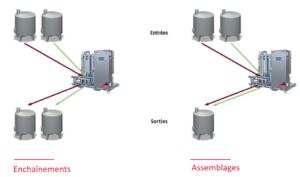

– Enables you to create filtration sequences or assemblies

– Protein stabilization of white and rosé wines

– Simplifying the wine processing chain

– Fewer cleaning operations for pumps, pipes and winery

– Wine treatment without the use of additives

– Wines available for bottling more quickly

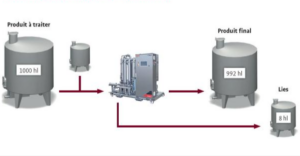

– No more tank bottom management, which can represent 3 to 5% of the volume treated

– Injection of up to 3 oenological products (e.g.: MCR, metatartaric acid, UF bentonite) and 3 at the filter outlet (e.g.: CMC, SO2, gum arabic).

– For wine filtration in closed tanks, up to 7 bars.

– Remote Pause / Start control (Example of use: help for filling tanks)

– Sterilizable sampling tap suitable for microbiological analysis

– When hot water production is far from the filter.

– For measuring and controlling the volume of wine entering the filter.

On-line measurement of turbidity in filtered wine

– Decarbonizes filtered wine. Dosage to be set manually by the operator

– Inert wine pipes upstream and downstream of the filter for better protection against oxidation

– Facilitates draining pipes

– Simplifies pipe rinsing

From performance to peace of mind, with Bucher Vaslin services.

Find a dealer

Selected for their professionalism, Bucher Vaslin dealers advise you and guarantee quality local service.

Join us

Interested in a career with Bucher Vaslin? Take a look at our job offers or apply directly on our website.