Technical check

During the technical inspection, our technicians follow Bucher Vaslin procedures to check the various components of your equipment, to test them and ensure they are operating correctly.

A general report will then be drawn up with the user to share the results and findings of the inspection.

- Checking the condition and functionality of main equipment components

- Real-time visualization of the operation of the machine’s components to identify potentially defective components

- Remote adjustment of settings

- Technical inspection is necessary to optimise the productivity of the equipment during its use.

- Reduced risk of production stoppages and machine downtime

- Functional condition of components at peak performance

- Increasing the service life of equipment

- Improving working and safety conditions for winery personnel

- User customers

- Accessible equipment and utilities in use (water, air, electricity, nitrogen)

- All Delta, Bucher and Sutter products

Preventive maintenance

Preventive maintenance is the phase following a technical inspection, during which defective parts are replaced (based on the customer’s validation of the estimate).

On equipment in the Flavy range, maintenance is triggered according to filter operating hours: it is carried out every 2,500 hrs and 5,000 hrs for Flavy FX models, and every 5,000 hrs and 10,000 hrs for Flavy X and Flavy FGC models.

This maintenance targets parts according to their degree of wear, with the aim of replacing them to preserve the integrity of the filter and maintain optimum productivity.

- Replacing defective components

- Functional preparation for the coming harvest

- In addition to functional testing for final verification

For equipment in the Flavy range

- Checking the condition and functionality of main equipment components

- Real-time visualization of the operation of the machine’s components to identify potentially defective components

- Replacement of wearing parts (depending on package)

- Preventive maintenance ensures equipment integrity, reduces the risk of breakdowns and ensures maximum productivity.

- User customers

- Accessible equipment and utilities in use (water, air, electricity, nitrogen)

- All Delta, Bucher, Flavy and Sutter products

Functional tests

The tests precede the harvest.

Before harvesting, the technician makes a final check that all the equipment’s functions are operational.

No parts are replaced and no maintenance is carried out. This is simply a dry run of the equipment.

- Checking functions on power-up (electrical, pneumatic, compressed air, water, nitrogen)

- Checking safety devices

- A reminder of the best practices to adopt to optimize harvesting machine productivity

Functional testing is an essential step for the successful start-up of equipment before the harvest.

- Ensuring equipment efficiency before the first inputs

- Winery teams feel at ease when they take up their duties

- Reduced number of machine incidents during the season

- User customers

- Accessible equipment and utilities in use (water, air, electricity, nitrogen)

- All Delta, Bucher and Sutter products

Overwinter lay-up

After the harvests and with the onset of winter, certain precautions should be taken to avoid possible inconveniences when starting up the machines again.

This operation takes place in October-November for the northern hemisphere, and in May-June for the southern hemisphere.

- Positioning and protection of functional parts

- Lubrication of rotating and sliding parts

- Energy shutdown

- Draining compressor reserves from machines, turbines, etc.

- Assessment of critical functional positions to anticipate and list any work to be considered for the next campaign

Extension of the service life of machine components

- Putting the machines in at rest condition

- Assessment of overall machine condition

- User customers

- Tidy and accessible equipment

- Cleaned according to operating instructions

- Utilities in service (air, water, gas, electricity)

- All Delta, Bucher and Sutter products

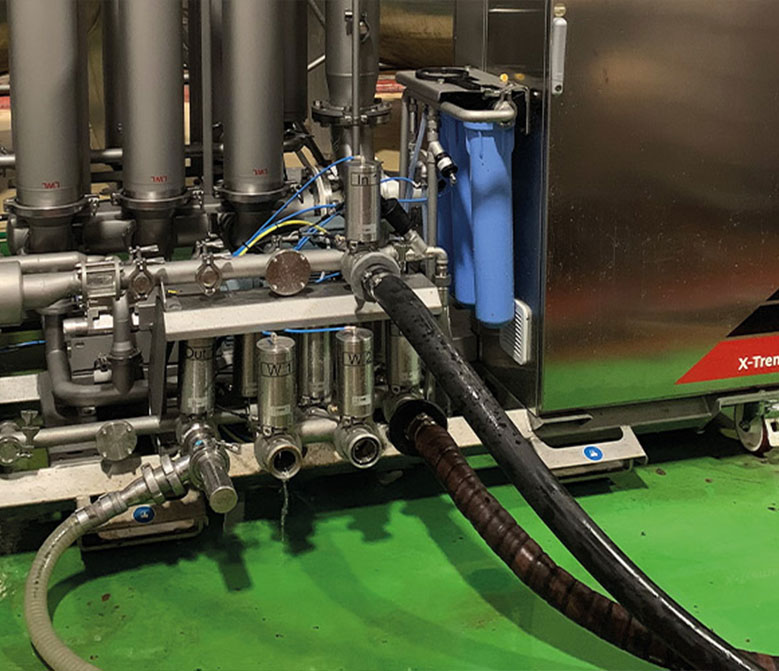

Passage wine/lees – lees/wine

The filter for the lees season will be equipped with :

- The 3mm modules required, if the filter is not a 2-in-1 version and is equipped with modules for wine filtration only.

- Installation or adjustment of lees scrapers

- Software & mechanical configuration of the filter in lees mode

Post-harvest, our teams put the filter back into configuration for wine filtration.

- Equipping the filter with specific lees filtration components

- Adapting machine settings

- Checking installation and machine environment

- Reminder of the best practices to be adopted in the respect of the Bucher Vaslin operating procedures

Preparing the tangential filter for the lees filtration period is an essential step in guaranteeing proper operation:

- Securing the lees filtration process

- Optimizing machine productivity

- Reminder of lees preparation recommendations

- User customers

- Accessible equipment and utilities in use (water, air, electricity, nitrogen)

- Flavy FX

- Flavy X-Treme

- Flavy X-Wine

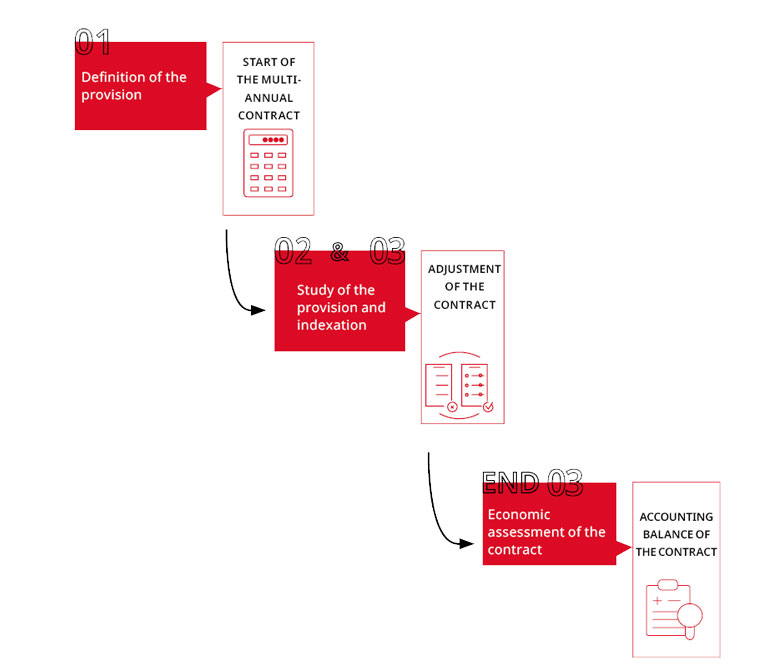

Multi-year contract

With the multi-year contract, the After-Sales Technical Manager works with you to define and refine the annual maintenance budget for your installation. This 3-year contract is designed to help you keep your maintenance costs under control, and anticipate maintenance contingencies with peace of mind. A review is carried out each year, and a final analysis of the technical operations is carried out at the end of the 3 years to adjust the forecast budget.

A calculation on the history of replacement of parts with the hours of assistance is made in order to offer you a first contract and its tariff.

At the end of the year, a comparison is made between the cost billed to the customer and the cost the customer would have paid had they not been under contract.

A new forecast is recalculated if the fixed amount is exceeded (upwards or downwards).

At the end of the 3rd year, a total balance sheet is drawn up, and the surplus portion compensates the other.

- Visibility and budget control

- Detailed monthly economic report

- Annual billing

- A fair deal

- 20% discount on parts purchase

- 5% discount on all labour services

- User customers

- Bucher Vaslin equipment only

- Bucher – Flavy – Delta – Sutter*

(*Made by Bucher Vaslin after 2011 “Sutter by Bucher Vaslin”)